Established in 1974, Comtherm Ltd has over forty years of experience in the design, manufacture, installation and commissioning of industrial combustion equipment for the commercial, industrial and process heating markets.

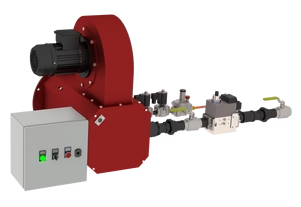

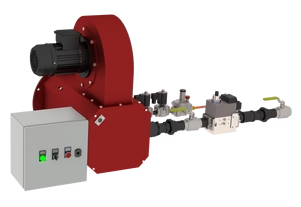

Introducing the EK Burner - a fully packaged combustion solution featuring integrated electrical controls and a pre-assembled valve train. Ideal for a diverse range of processes, such as powder coating lines, cure ovens, spray dryers, and more.

With its sleek and compact design, the EK burner seamlessly integrates into virtually any application. The versatile design allows you to choose from multiple control options, including on/off, high/low, and modulating gas.

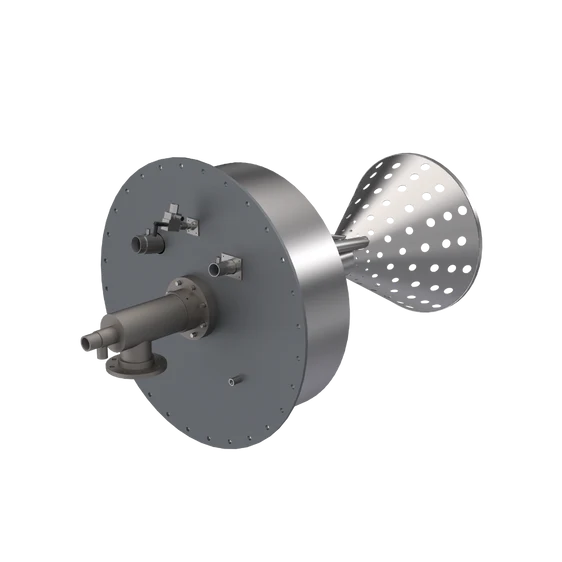

The ‘FC’ burner series of ‘FUME CONE’ gas burners have been specifically developed for fume incineration applications on a wide range of industrial plants; typical applications include the incineration of exhaust fumes from paint solvent and removal of smoke from curing ovens. The nozzle and lance are manufactured using high grade, heat resistant stainless steels whilst the cone is manufactured from a very high quality, heat resistant Inconel alloy. This maximises plant life and increases operating reliability. The complete FUME CONE burner assembly normally consists of the fuel nozzle, cone and lance assembly with insulated mounting plate, gas valve assembly and controls package.

The IL gas burner head is designed to suit virtually all types of low temperature, gas fired air heating applications. The iL burner is constructed using a series of modules. Each 150mm module is capable of an output of 75kW with a head pressure of 10mbar natural gas and 100 kW with a head pressure of 18 mbar. The iL-HC unit has an output of 150kW per 150mm. The burner is available with a cast iron or cast aluminium manifold. The IL can be fitted into process air ducts having velocities of 5 to 25m/sec. Airflow should be uniform across the air duct, both upstream and downstream of the burner. All the air required for combustion is supplied by utilising the process air.

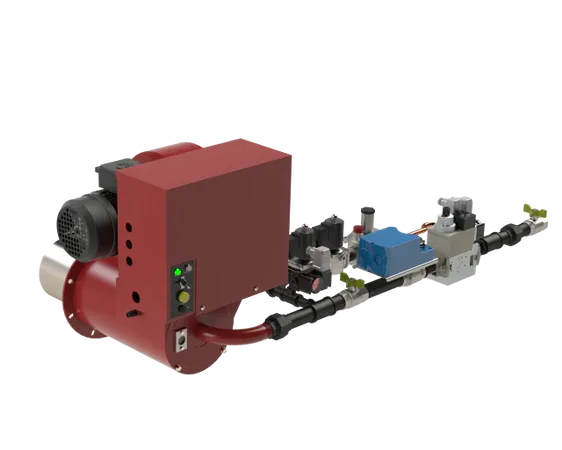

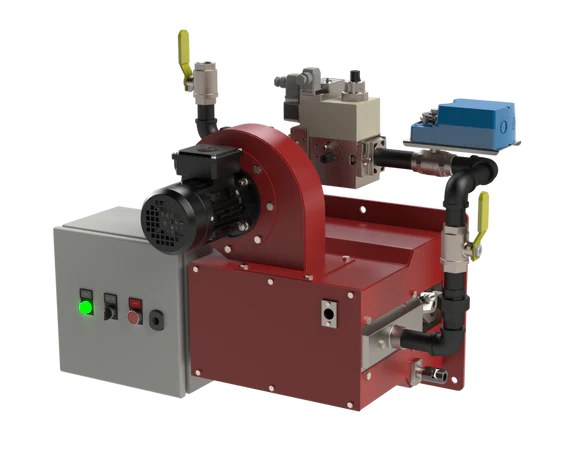

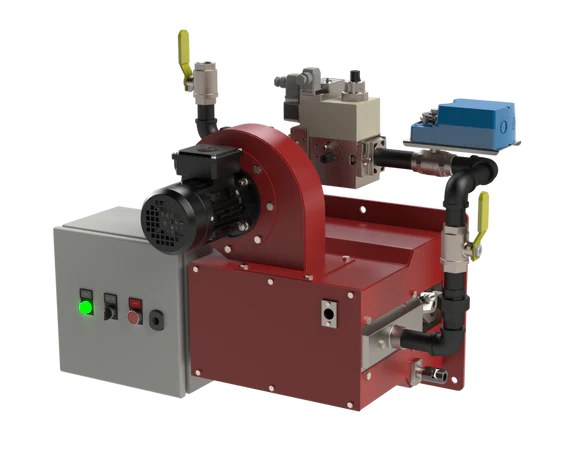

The ‘PC’ series of burners are packaged units designed to suit virtually all types of industrial gas fired applications. The packaged nature of the PC burner enables simple installation. All units are pre-fired and tested before leaving our works. The design of the PC burner allows the equipment designer complete flexibility in their application as they can be adapted to suit the layout of the plant. The units are suitable for all commercially available gases and can be configured to work on low calorific fuels such as syngas and biogas. The robustness and flexibility of the burners allows them to be used in many industries including food, automotive, aerospace, materials finishing, minerals processing and ceramic drying.

The ‘PCF’ series of burners are packaged units designed to suit virtually all types of industrial gas fired applications. The packaged nature of the PCF burner enables simple installation. The design of the PCF burner allows the equipment designer complete flexibility in their application, as they can be adapted to suit the layout of the plant. The units are suitable for all commercially available gases and can be configured to work on low calorific fuels (such as syngas and biogas). The robustness and flexibility of the burners allow them to be used in many industries including food, automotive, aerospace, materials finishing, minerals processing and ceramic drying.

The PH and PH-C series of gas burners are designed to operate in systems where short flames and high turndown ratios are required. The burners consist of a flange mounted, in-line combustion head which is available in Straight, T and X sections. This enables the burners to be constructed to suit the appliance layout. The units are modular; therefore, they can be constructed to give any output capacity required.

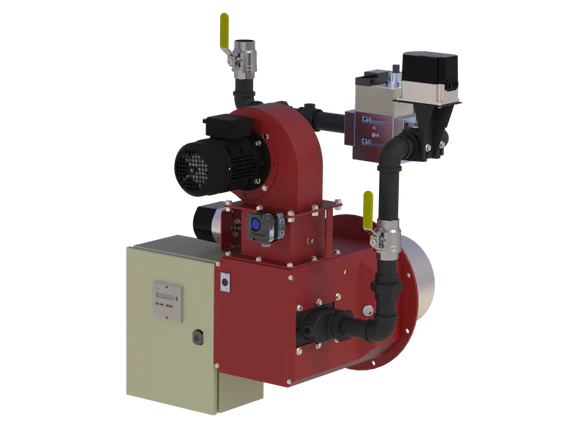

The PP series of gas burners are pre-packaged, fan assisted units designed to suit virtually all industrial gas fired applications. The PP burner utilises the well proven Comtherm PH burner head and combustion system; this ensures a stable, short flame with low emissions. The short flame produced makes the burner ideal for applications where chamber length is restricted. This burner range has been successfully applied in many industries including food, textiles, steel, plastics, paper and pulp. The compact dimensions of the PP burner and its short flame allows the plant designer a high degree of flexibility in its application.

The RSP series of gas burners are pre-packaged, fan assisted units designed to suit virtually all types of gas fired applications where recirculated air is utilised; typical applications include the firing of industrial ovens and dryers. The RSP can be fitted into process air ducts having air velocities of 5 to 30m/sec. The burners can be installed in a process plant recirculation system where it is not possible to construct a combustion chamber and install a conventional type of burner assembly. The RSP burners consist of an ‘in-line` PH type combustion head mounted on a side plate so as to fire parallel to the side plate in the direction of air flow.

The SP series of gas burners are pre-packaged, fan assisted units designed to fire applications where fresh air is to be heated from ambient temperatures up to plant requirements; typical applications include industrial spray booths and drying rooms. The SP can be fitted into air ducts having air velocities of 5-30m/sec.

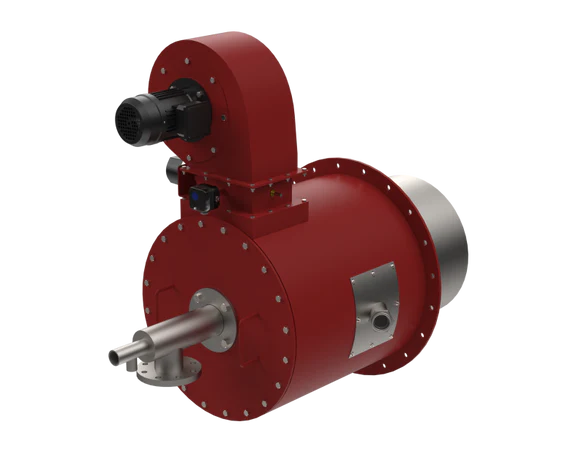

The TF burner series of packaged gas burners have been specifically designed for the firing of immersion tubes installed in liquid tanks.

TF burners are blown units, this means that there is no requirement for a suction exhaust fan on the tube. This enables simple installation and low maintenance. The unit is simple and safe to operate. All burners are pre-fired and fully tested before leaving our works.

The TFR burner series of packaged gas burners have been specifically designed for the firing of immersion tubes installed in liquid tanks.

TFR burners are blown units, this means that there is no requirement for a suction exhaust fan on the tube. This enables simple installation and low maintenance. The unit is simple and safe to operate. All burners are pre-fired and fully tested before leaving our works.

The ‘TFR-HT’ burner series of packaged gas burners have been specifically designed for the firing of high-temperature ovens. The TFR-HT burner utilises a standard Comtherm PC nozzle mix burner head.

The burner uses a split combustion cone head where the air is introduced into the flame at three points and provides cooling for the combustion tubes. This feature produces a high burner exit velocity with excess air capabilities in the region of 3000%. They are intended for application where the high process temperature prohibits the use of standard PC burners or where high-velocity tempering air is required. The TFR-HT burners are suitable for oven temperatures up to 900°C.